Heat Treating

Accurate Tooling Solutions specializes in heat treating all steel to prevent distortion or cracking near welds during machining and cold strained areas during processing. Heat treatment is also applied to flame cut edges and to normalize steel. Applying a heat range of 950° to 1150° to steel refines its grain structure to a more uniform consistency, thereby improving its machine-ability.

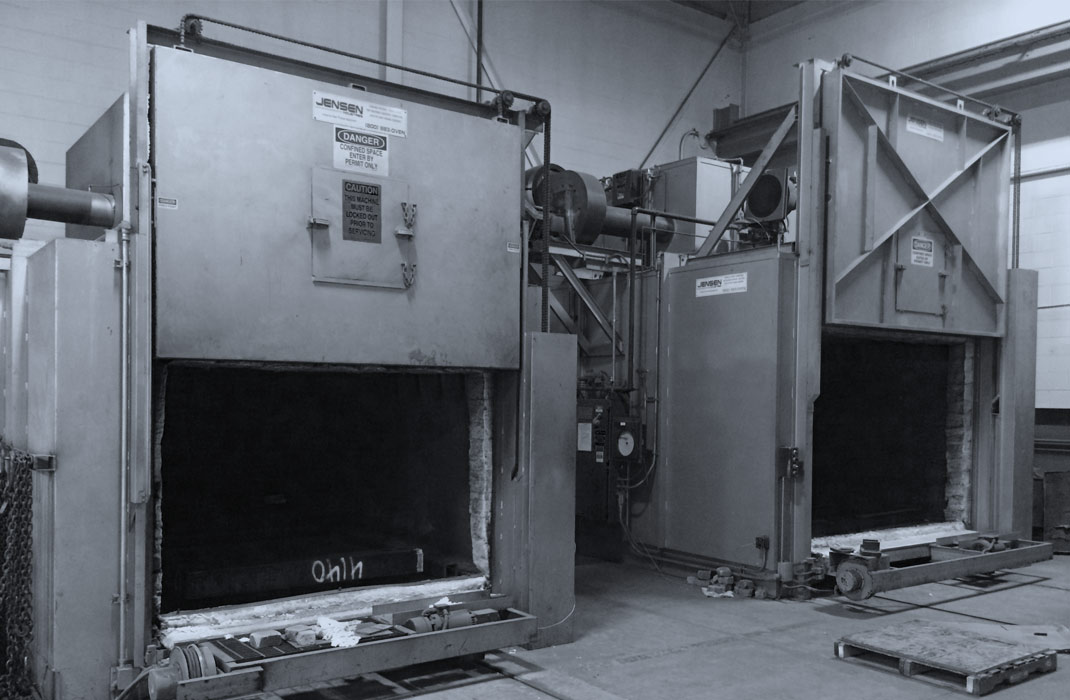

We have three onsite ovens to accommodate any size job, including our large capacity furnace powered by a single high-velocity jet burner.

To ensure that the job meets your specifications, we utilize the following ovens:

GRIEVE 44″ L X 24″ W X 24″ H

JENSEN #1 132″ L X 80″ W X 56″ H

JENSEN #2 138″ L X 95″ W X 72″ H

Our Facility

Our new 75,000 square foot facility packs the latest in tooling technology. Take a tour and see our capabilities.

Our Projects

See our latest assembly jigs, billet tools, cure tooling and more. All built with precision and craftsmanship…that’s accurate.